Share

High-performance fine stone concrete production line

Need to find the right solution, please contact our technicians, Contact us!

Classification

Label

- Product Description

-

1、

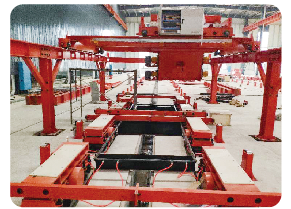

Steel pallet circulation system

The formwork circulation system includes: formwork circulation system, ferry unit, and formwork platform

Mold platform circulation system

The mold and platform circulation system adopts a variety of control modes, and the hand can be automatically switched at will, to realize the synchronous circulation of the mold and platform, and effectively reduce the manu al operation;

Ferry unit

The ferry car is the whole car transverse transportation mode, using servo frequency conversion and high-precision sensor positioning, the ferry car runs synchronously and smoothly;

Model platform

The formwork platform is the key to ensure the flatness of the fine stone concrete reinforced steel frame composite plate, including the millimeter level error.

The overall lightweight design,to improve the maintenance thermal efficiency, can be customized;

2、

STEEL PALLET PRE-TREATMENT SYSTEM

The mold pretreatment system includes: cleaning unit, drawing unit and release spraying unit

Cleaning unit

The formwork cleaning unit will be attached, and the concrete residue scattered on the formwork platform will be treated clean, and the cleaning and vacuuming device will be used to handle the hopper to ensure the hygienic working environment.

Line drawing unit

The line drawing unit is automatically completed by the CNC marking machine. The automatic The line drawing unit is automatically completed by the CNC marking machine. The automatic elevation induction device handles the graphics according to the actual requirements, and the precise positioning system ensures the accuracy of the graphics.

Release agent spraying unit

The release agent spraying unit can realize automatic spraying of the release agent, uniform spraying and convenient maintenance.

3、

Rebar truss grab system

Rebar truss grasping manipulator

It can achieve a multi-channel frame capture and place it on the mold table. Two sets of raw material cars guarantee the beat of the whole production line.

Horizontal type steel bar truss revolving truck

For the accurate positioning and storage of steel truss line, improve the overall production rhythm on the line.

4、

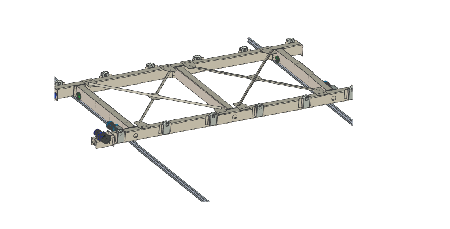

Concrete mixing fabric vibration system

Concrete mixing cloth vibrating system includes: concrete mixing station, fully automatic cloth machine, hydraulic vibrating platform

Concrete batching plant

It can achieve automatic feeding, automatically weigh and transport various raw materials in proportion to the mixer, and after uniform mixing, transport them to the fabric machine; Equipped with supporting facilities such as automatic flushing, automatic feeding, and scheduling system;

Automatic fabric machine

Adopting seamless mixing and precise spiral fabric form. Using servo motor drive and gear rack walking, precise fabric distribution is achieved. The weighing system automatically adjusts the cutting speed and walking speed according to the required weight, achieving automated production. Adopting stainless steel lining and high wear-resistant spiral shaft, extending the service life.

Automatic fabric machine

The vibration unit is composed of the vibration mechanism, the air spring and the shock absorption mechanism.

The concrete used for vibrating and dense pouring can eliminate the bubbles inside the concrete and ensure the uniform distribution of aggregate inside the concrete.

Adopt the multi-stage vibration reduction form to effectively reduce the working noise.

5、

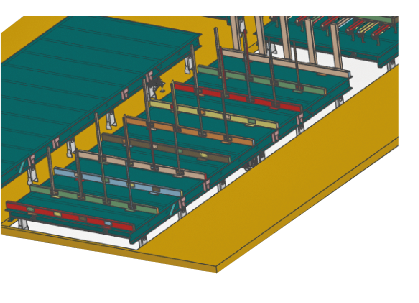

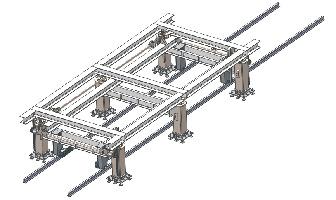

Stacking and curing system

The maintenance system includes: mobile stacker, three-dimensional support mechanism, and maintenance control system

Mobile stacker

Mobile stacker cranes can achieve multi station stacking and storage, using hydraulic lifting systems for smooth operation and significantly improved efficiency. Mobile stacker cranes reduce workshop usage area.

Three-dimensional support mechanism

Supporting the maintenance platform on the workstation without affecting the passage of the assembly line platform better ensures the stability of the fine aggregate concrete components.

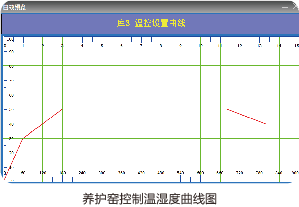

Maintenance control system

The maintenance control system adopts PDI algorithm control, and the temperature and humidity inside each maintenance kiln can be automatically adjusted to achieve precise control of temperature and humidity according to the curve, ensuring that the strength of the components meets the lifting requirements.

6、

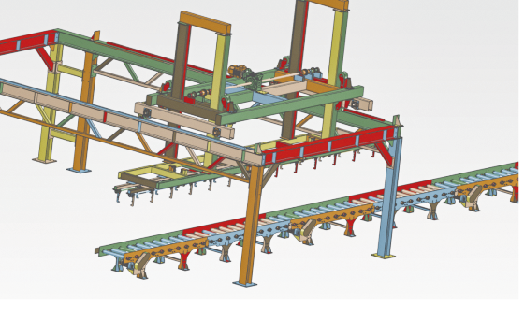

Finished product production line system

Finished product offline system includes: finished product offline manipulator, translation type finished product conveyor vehicle

Finished product offline manipulator

Finished product offline manipulator: used to capture the finished product components on the production line offline. The performance is stable and reliable, and by a set of finished product component transportation device to facilitate the cost of lifting and transfer;

Translation-type finished product transport vehicle

The translation finished transport vehicle serves as the turnover of the finished components, the finished components are stacked by the finished line manipulator, and the translation transport vehicle is transported to the next station.

7、

CENTRAL CONTROL SYSTEM

The central control system is the nerve center of the entire automated production line, with functions such as video surveillance and warning. It coordinates and controls the production of the entire factory, and the operating status of the production line is clear at a glance. The central control system sends instructions to each independently controlled system to monitor the working status of various system equipment, timely alarm devices with hidden dangers and faults, automatically diagnose and handle faults, and ensure the normal operation of the production line.

8、

Products and applications

High-performance fine stone concrete production line

Need to find the right solution, please contact our technicians, Contact us!

Classification

Label

Product inquiry

Note: Please leave your mobile phone and E-mail, and our professionals will contact you as soon as possible!