Share

Automatic quantitative pre-XL-PSD1400 machine

Need to find the right solution, please contact our technicians, Contact us!

Classification

Label

- Product Description

-

Product composition system description

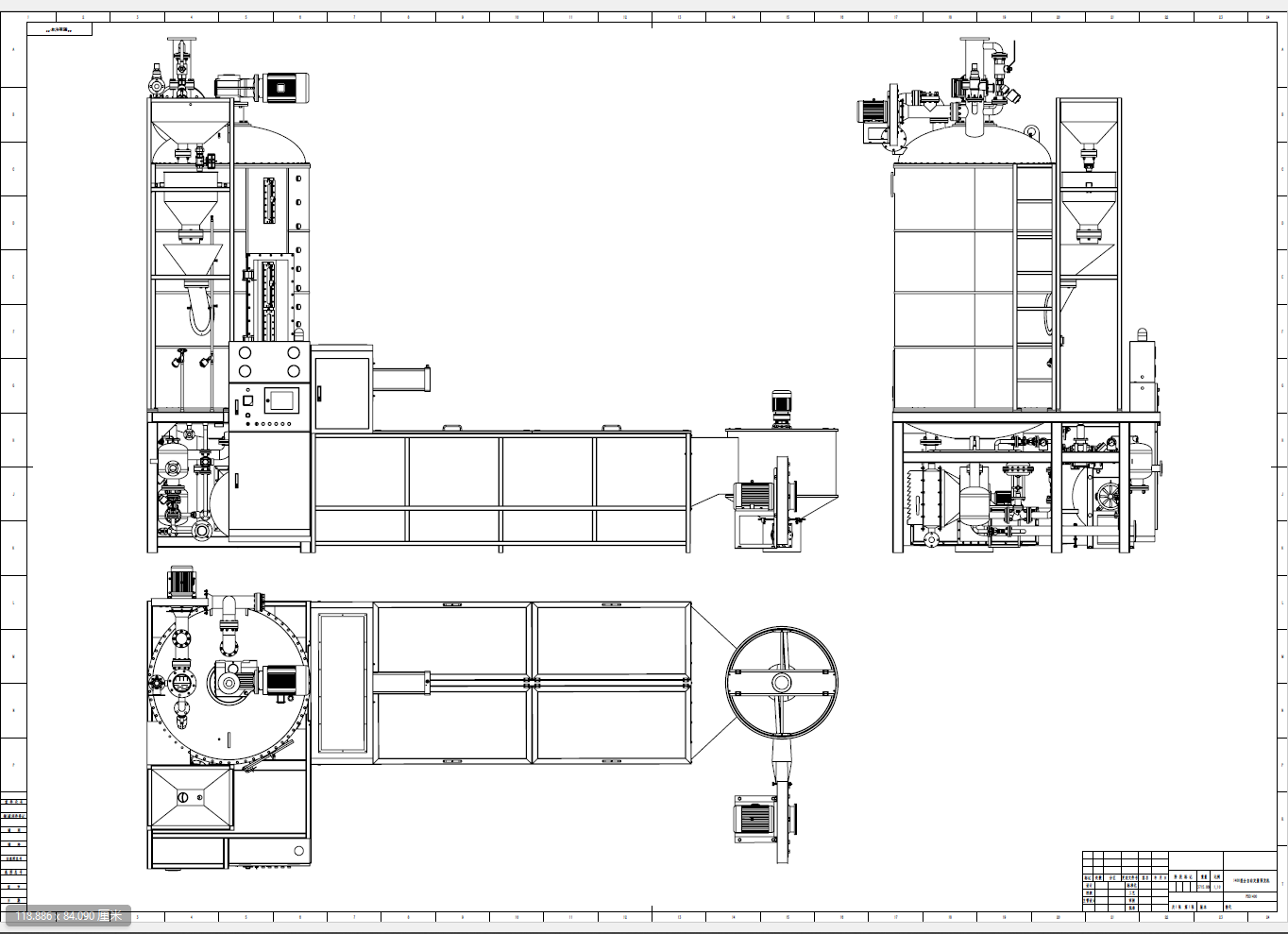

XL-PSD full-automatic intermittent pressurized quantitative pre-development machine is developed, designed and manufactured by our company according to the new situation in China. It consists of a quantitative pressurized pre-development machine, a vulcanization, drying, screening, crushing, and conveying device, etc. Full-automatic circulating foaming system. It is suitable for pre-foaming of expandable polystyrene (EPS) foam products, and is a necessary machine for foam products factories.

Performance characteristics

1. The automatic quantitative pre-release machine produced by our company can perform both a foaming and a secondary foaming. It is a multifunctional pre-release machine.

2. The electronic control system of the whole machine adopts the PLC programmable controller produced by Omron Company of Japan and the touch screen produced by Taiwan. The electrical spare parts are made of famous brands at home and abroad, with reliable action, low failure rate and convenient operation of on-site modification and recording data.

3. Solenoid valve, butterfly valve, angle seat valve using domestic and foreign well-known enterprise products. The material is all stainless steel, flexible action, long life, ensure and improve the operation reliability of the machine.Main technical parameters of products

Project Unit PSD1400A Foaming barrel body mm 1400*2250 effective volume m3 2.5 Steam pipe inlet mm DN50 Steam pressure MPa 0.4~0.5 Steam consumption Kg/cycle 13~15 Compressed air inlet Inches 1 Compressed air pressure MPa 0.6~0.8 Compressed air consumption m3/cycle 0.4~0.6 Blowdown Exhaust mm DN150 Drain mm DN80 Motor

Power

Spindle reducer KW 7.5 auger motor KW 3.0 discharge fan KW 2.2 Total installed power KW 12.7 Electricity consumption kg/h 8 to 10 foaming density Once kg/h 10~30 production capacity 12g/l once kg/h 530 15g/l at a time kg/h 670 20g/l once kg/h 1200 30g/l at a time kg/h 1400 Exterior dimensions L×W×H mm 2800 × 2500 × 4900 Foaming cycle S 90~140 Machine weight t 2.6 Main product configuration

Serial Number Name Brand 1 PLC Omron 2 Digital output module Omron 3 Touch screen complicated and easy 4 IoT Plug-in complicated and easy 5 Contactor Delixi 7 Thermal overload relay Delixi 9 Intermediate relay Omron 10 switching power supply Omron 11 Solenoid valve group Yadke 12 Pressure transmitter Fizeau 13 Butterfly valve Good workers in Hangzhou 14 angle seat valve Shanghai Hongpeng 15 Proportional valve Hebei Xibo 16 Pressure reducing valve Yoshida Kai 17 Cylinder Yadke 18 Reducer Zhejiang Constant Tooth Product Attached Drawing

Automatic quantitative pre-XL-PSD1400 machine

Need to find the right solution, please contact our technicians, Contact us!

Classification

Label

Product inquiry

Note: Please leave your mobile phone and E-mail, and our professionals will contact you as soon as possible!